At this year’s SOAR (Spin Off Autumn Retreat), Yarn Barn will be parting with Rick Reeves’s last Saxony wheel, which has been part of their collection for years. It is signed and will be available at their booth in the SOAR marketplace. It's a beauty!

This felt like the perfect time to revive this profile of Rick and Marge Reeves that was originally published in Spin Off Fall 2017. A few months after the article was written, we were saddened to learn of Rick’s death on February 21, 2017, but this is an enduring reminder of his work and life. —Editor

Between 1964 and 2001, Rick Reeves produced 11,129 spinning wheels and thousands of spinning tools. He made lazy kates, spinning chairs, winders, and, of course, distaffs and innumerable bobbins as well. The wheels alone required at least 52,000 hours of wood turning. Some wheel makers produce three or four wheels a year; Rick produced three hundred to six hundred annually . . . and spun on every wheel before it left his shop.

“I was never ‘in business,’ ” said Rick in November 2016. As a teenager, he was interested in aviation, flew model planes, and belonged to the Civil Air Patrol. He repaired other kids’ bicycles, set pins in the bowling alley, ran projectors and popcorn makers in the movie theater, and built a still. Later he started wood turning and making candleholders and other items in his backyard shop while employed as a metalworker. Urged to show off his skill as a woodworker at the Iowa State Fair, in a booth located amid displays of fudge, candles, and sausages, he turned wood twelve hours a day and sold enough of his work to pay for the booth.

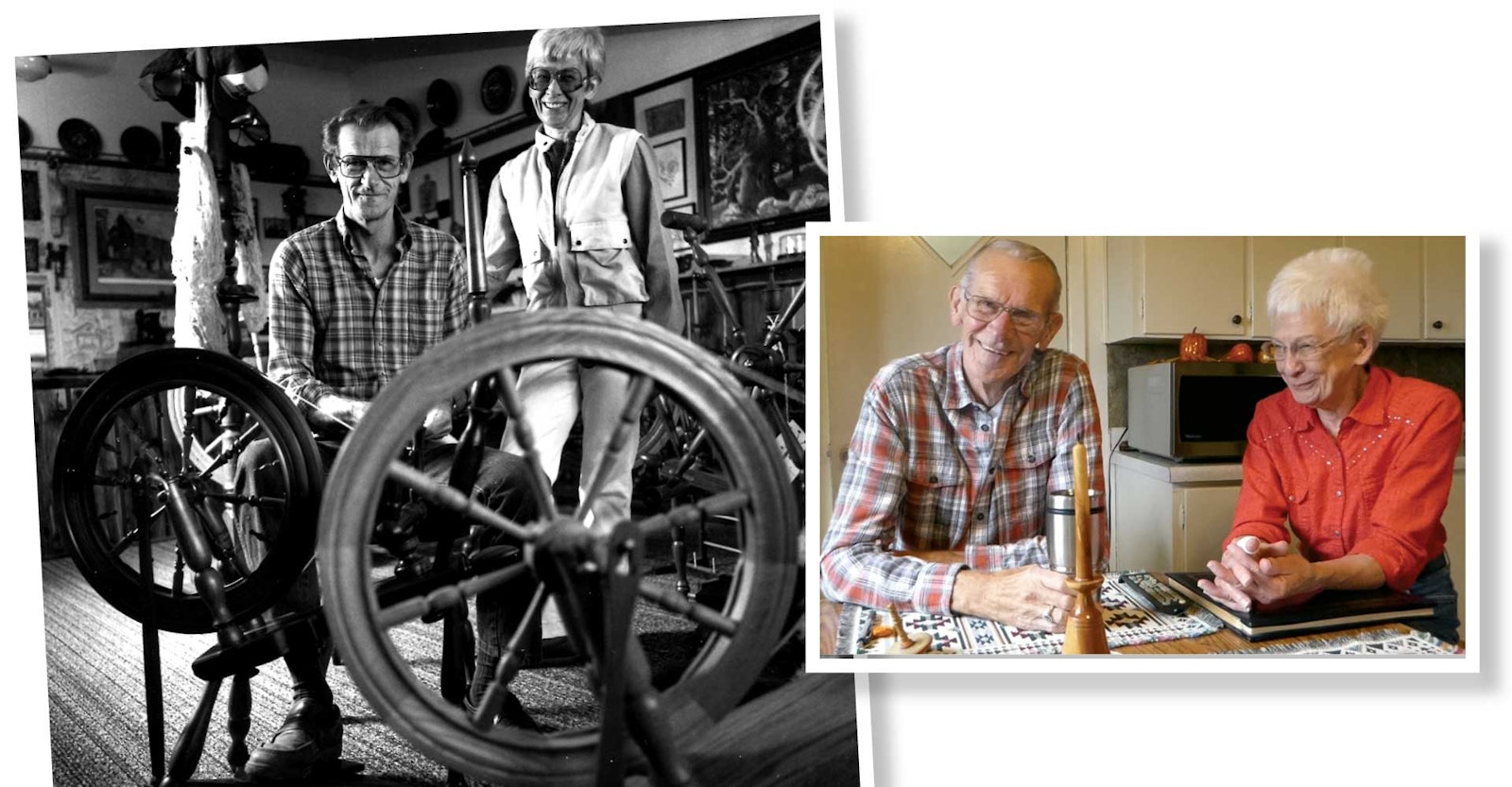

One day in 1964, Eleanor Mast, a longtime spinner living in Waterloo, Iowa, brought a wheel to Rick’s shop in rural Waverly and asked if he could make some replacement parts. Rick had always made machinery—things that do something—and Eleanor’s challenge intrigued him. He looked at wheels in the collection at the Vesterheim Norwegian-American Museum in Decorah, Iowa. Designing and building spinning wheels soon became a fascinating hobby. Rick saw his early wheels, made in the 1960s and 1970s, as learning experiences. He kept “going down dead ends” and developing new solutions. Eventually Rick and his wife, Marge, quit their jobs and focused on creating an efficient workshop to craft the finest spinning wheels.

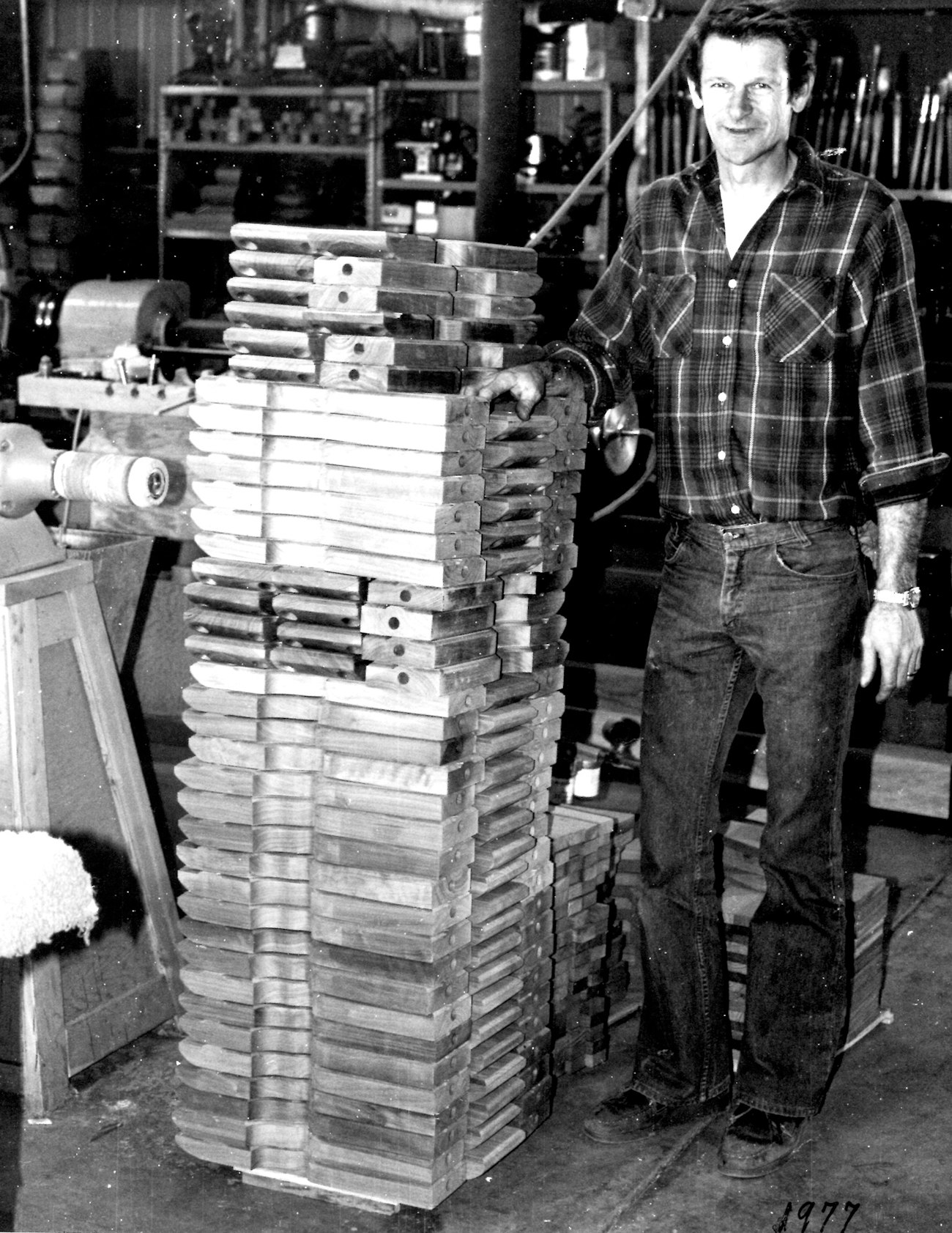

Rick and Marge rented an old house in West Amana in 1975. They set up shop in Norman Schanz’s workshop in the Amana Colonies, seven Iowa towns founded as a self-sufficient community that became an economic and tourist destination. The Reeveses were the first “outsiders” to be invited to work in the Amana Colonies. At the time, Rick made novelty items. Twenty-five tour buses a day would empty out in front of the shop, and Rick had to turn enough lamps, candle stands, bells, and cribbage boards to meet demand. At that time, he was producing a wheel or so per month in his spare time.

Rick Reeves in his workshop in 1977

Rick Reeves in his workshop in 1977

In 1980, Rick and Marge had a workshop built south of the Amana communities and off the tour bus line. (Moving to Marengo, he also stopped using the Amana name, so folks at the woodturning shows wouldn’t complain to him if their Amana kitchen appliances needed repair.) Rick sold wheels to tourists, but he also started attending spinning events and shipping wheels to customers. Although he made standard wheels to have on hand at the workshop, he also took orders from spinners and constructed each new wheel individually. At the time the Marengo shop opened, Rick had four hundred wheels on order and needed to get busy. Marge ran the business, sanded and finished the wheels, and ran loads of lumber through the planer. Within a few years, spinners were using Rick’s wheels in Canada, Turkey, Colombia, and other countries around the world as well as all fifty states.

Rick’s first wheels were made primarily of local black walnut. When he obtained a nice piece of burled or spalted wood, he could create something uniquely beautiful. Some wheels had exquisite finials, carved figures on the uprights, and rings on the spindles. Marge was in charge of finishing the wheels with a four-coat, hand-rubbed finish. The finishing process took longer than the wheel-building process and could not be rushed. When Marge hurt her arm and was unable to work on the wheels for a while, and the supply of cherry and walnut was declining, Rick started making wheels from local vacuum-dried red oak and selling them unfinished or oiled. The staff of the Iowa Economic Development Authority had been urging Rick to expand and speed up his operations; easier to turn and faster to finish, oak permitted Rick to make those changes.

Rick started with a 19-inch Saxony style for his first oak wheels, then standardized the process to make his workshop more productive. Bigger, faster, and better lathes were added to the workshop. A Reeves Woodworks brochure from the Marengo shop shows three Saxony wheels with wheel diameters of 19, 24, and 30 inches, a 14-inch castle wheel, a 19-inch frame wheel, a 24-inch double-bed Norwegian wheel with a dozen finials between the spokes, and a spinning chair. Soon Rick expanded the line to thirteen different models in oak and ash. He found pictures and descriptions of Irish wheels in the Ulster Museum collection and adapted these designs for utility and beauty. He copied an interesting lateral wheel and built three like it. He also produced a kick wheel for a spinner with disabilities.

Rick Reeves at the 1996 Spin Off Autumn Retreat in Missouri, surrounded by his wheels. Photo courtesy of Spin Off

Rick Reeves at the 1996 Spin Off Autumn Retreat in Missouri, surrounded by his wheels. Photo courtesy of Spin Off

Every year, Marge and Rick traveled 50,000 to 60,000 miles in a customized van to major shows and smaller fiber events around the country. When Rick and Marge were at home in Iowa, production in the new workshop had to be continuous and speedy to keep up with demand, but the pace did not feel frantic to the prolific wheel maker. Rick described the workshop as “very casual. You can get more done in a relaxed atmosphere.” Marge agreed, saying, “It didn’t really seem as if we were working.”

In addition to producing wheels and other spinning equipment, Rick offered advice to other woodcarvers and woodworkers. Over the years, he invited a number of young men to try their hands at wood turning in his shop and learn his methods for efficiency and creativity. Rick’s workshop has also spun off other businesses such as Carl Lee’s workshop in Missouri. Carl’s mother, Carol Lee, had been a distributor of Rick’s wheels, and Carl now makes replacement bobbins for Reeves wheels.

Rick and Marge Reeves have friends around the world: wheel makers, wood turners, spinners, and more. Not long before his death, Rick still did some wood turning with friends but missed discussing wheel designs and ratios with other luminaries of the wheel-making community.

Schacht Spindle Company now makes popular 24- and 30-inch Schacht-Reeves spinning wheels based on two of Rick’s Saxony models. “Rick Reeves was a creative and accomplished wood turner who understood his materials and the needs of his customers,” says Barry Schacht of Schacht Spindle Company, Inc. “His long partnership with his wife, Marge, gave the spinning community an approachable team and beautiful, technically excellent spinning wheels.” Rick and Barry collaborated to redesign Rick’s wheel so that parts can be made by machine rather than by hand.

Schacht Spindle Company has two original Reeves wheels in its collection, which served as the seed for the Schacht-Reeves spinning wheel collaboration. Photo by George Boe

Schacht Spindle Company has two original Reeves wheels in its collection, which served as the seed for the Schacht-Reeves spinning wheel collaboration. Photo by George Boe

Although Rick turned his last wheel in 2001 and sold his workshop, eager buyers have created a brisk online market for used Reeves fiber tools. On the Ravelry pages for the Reeves Spinning Wheel Owners group, enthusiasts post photos of their wheels, and until his death, Rick checked in regularly to respond to questions. Rick explained why the identification numbers on his wheels do not indicate precisely the sequence of wheel construction: The workshop was busy, and there might be a number of visitors there. When Rick had a few moments free, he’d write numbers on the bottoms of the new bed blanks in order, but by the time the beds and other parts were shaped and assembled into wheels, they would not necessarily be finished in that same order.

Not every Reeves wheel was labeled as his; about one hundred of Rick’s 19-inch Saxony wheels (unsigned and crafted in maple rather than oak) were shipped to Plattsburgh, New York, for Leclerc to sell to customers in the United States. Rick acknowledged that in his dedication to producing high-quality spinning wheels for nearly forty years, he was neither persnickety about the serial numbers and brass plates nor obsessive about signing the bottom of each wheel. “It wasn’t a piece of art,” he says. Those who spin on his wheels, however, would argue that each Reeves wheel is indeed a brilliant design and a magnificent work of art.

This article was first published in Spin Off Fall 2017.

Also, remember that if you are an active subscriber to Spin Off magazine, you have unlimited access to previous issues, including Fall 2017. See our help center for the step-by-step process on how to access them.

Resources

- Anthony, Lyndal. “Rick Reeves Custom-Made Spinning Wheels.” American Woodturner, 26, 6 (December 2011), 46–47.

- Farwell-Clay, Julia. “The Future of Custom Wheels.” Spin Off, 35, 3 (Fall 2011), 60–62.

- Nandell, Bob. “Iowans’ Spinning Wheels Are Not Just for Decoration.” Des Moines Sunday Register Picture Magazine, August 3, 1980, 1–3.

- Noble, Linda, and Kaye D. Collins. “Behind the Scenes: At Schacht Spindle Company.” Spin Off, 28, 4 (Winter 2004), 26–28.

- Reeves, Marge, and Rick Reeves. Interview with Karen Agee, Becky Metcalf, and Colette Ubben on November 18, 2016, in rural Plainfield, Iowa.

- Thompson, George Barton. Spinning Wheels (The John Horner Collection). Belfast, Ireland: Ulster Museum, 1964.

Karen Agee, Becky Metcalf, and Colette Ubben are members of the Northeast Iowa Weavers and Spinners Guild and the Iowa Federation of Handweavers and Spinners. Becky has one of the earliest wheels crafted by Rick and Marge Reeves.

Dennis Reeves, Rick’s nephew, posts photos of Rick’s early work on his site at http://dreevesinc.com/rickreeves.html.