|Sponsored|When Schacht Spindle Company first started making the Matchless spinning wheel in 1987, it featured one treadle, as did most wheels at the time. “Suddenly, double treadles took hold,” says Barry Schacht, the founder of Schacht Spindle Company. “It’s especially useful with castle wheels because of the balanced body position—just like riding a bicycle.” So Schacht adapted their spinning wheel to have the option of two treadles. In no time at all, the double-treadle model outsold the single-treadle by a mile.

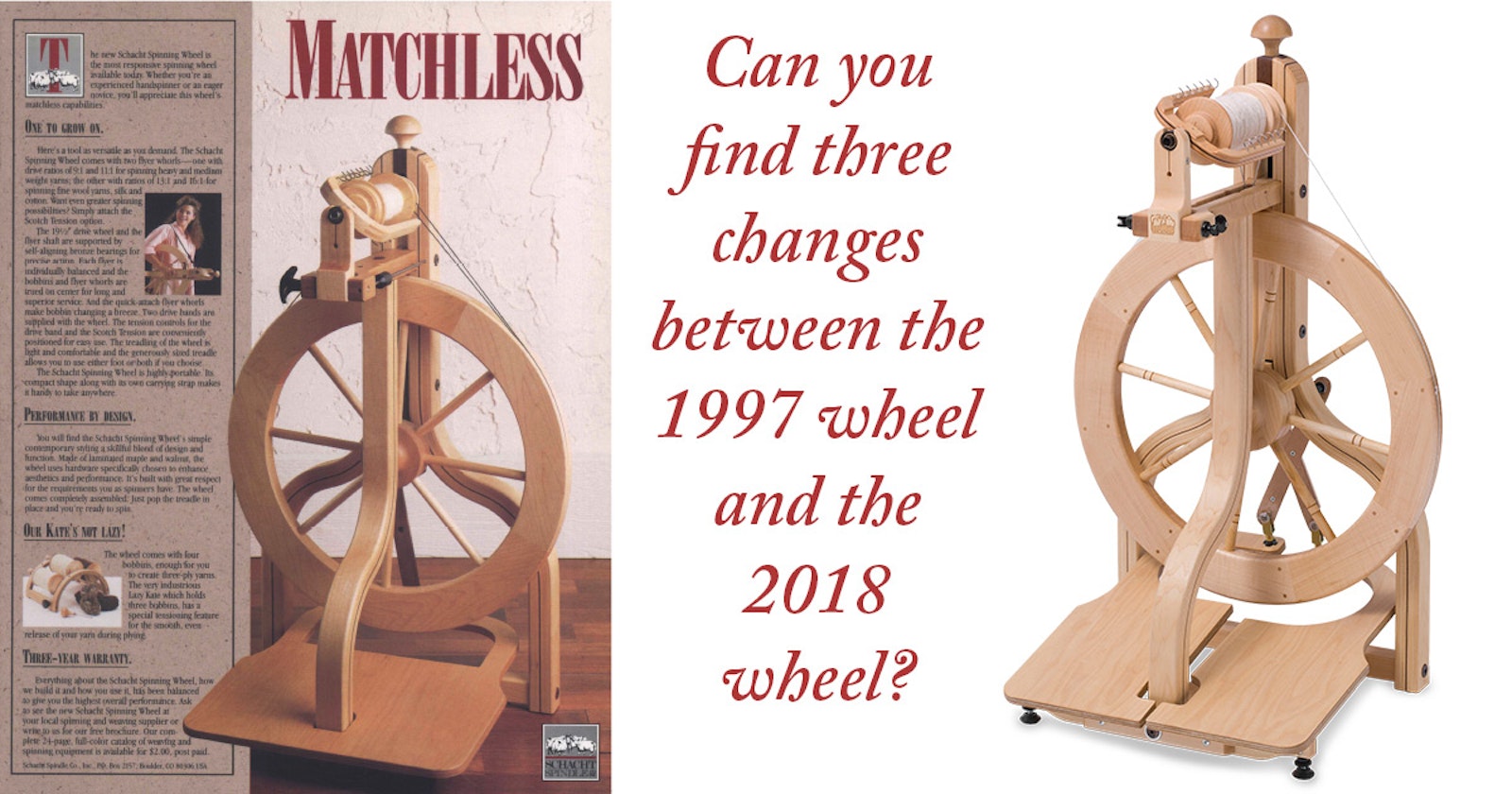

The number of treadles isn’t the only innovation Schacht has incorporated into its wheels. At first, the front maiden on the Matchless was loosened by a knob, but around the time that they introduced the lighter Ladybug spinning wheel, the front maiden mechanism changed to the kind of quick-release device that’s used on the front wheel or seat post of a bicycle.

A Whole Different Kind of Wheel

“Little things came from the experience in the bicycle business,” Barry says. He began a second business, Mirrycle Corporation, when he wanted a bicycle mirror in 1979. Now it shares a building with the spinning wheel and loom factory. Although Mirrycle stays away from bicycle wheels, Schacht has incorporated several improvements from bicycles into their spinning wheels.

A Whole Different Kind of Wheel

“Little things came from the experience in the bicycle business,” Barry says. He began a second business, Mirrycle Corporation, when he wanted a bicycle mirror in 1979. Now it shares a building with the spinning wheel and loom factory. Although Mirrycle stays away from bicycle wheels, Schacht has incorporated several improvements from bicycles into their spinning wheels.

And it’s not just Schacht’s own innovations that make their way into their products. “Consumers give us some of these ideas,” Barry says. “They may have an issue with something, and consumer input is always important. It’s our belief in constant improvement.” It was consumer demand, after all, that led to that second treadle.

Embracing the Retrofit One unusual aspect of Schacht’s business is backward-compatibility. If you have a Matchless from 1987, you can send it back to the factory to be converted to double-treadle. If you want extra bobbins, you can order them at the same time—they’ll fit your old flyer. In fact, many Schacht spinning wheels make a trip back to the factory for tweaks, updates, or reconditioning.

“The idea is, it’s great to do constant improvement, and it makes our products work better,” Barry says. “As our knowledge of componentry and the way things work increases, why not apply them? In most cases, our equipment is not obsolete.” (Imagine if you could retrofit your 1987 bicycle—let alone your—phone with the most recent technology!)

Who knows what the next improvement in spinning wheels will be?

—Anne Merrow

Learn more about your spinning wheel!