Predrafting sparks intense controversy. Some spinners swear by predrafting spinning fiber, or gently pulling fibers a short distance forward out of a combed top or roving prior to spinning. Spinners such as Maggie Casey use the technique as needed; others scoff and scold at the very thought. Whether you normally predraft or not, some fibers call for a hybrid method to loosen without actual drafting.

Cashmere and Cotton Case Study

While I was participating in Spinzilla one year, I worked with amazing fibers from two dyers: Lisa Souza Dyeworks cashmere and Merino 50/50 blend and Chasing Rainbows Dyeworks cotton sliver. Both fibers were mechanically processed prior to being dyed, which lends itself to the dapples of color and shading that we spinners adore. During the dyeing process, the fibers are wetted, exposed to heat in some cases, and then dried. This can create subtle (or not so subtle) compaction, making the fibers harder to draft. The cashmere/Merino and cotton sliver used here are examples of high-quality spinning fibers that have been carefully dyed that can be gently loosened to make spinning easier. Aggressive predrafting could do more harm than good. Loosening the fibers from side-to-side is another option.

On the left, I’m predrafting, or pulling the fibers forward out of the fiber supply. On the right, I am loosening the fibers from side to side.

On the left, I’m predrafting, or pulling the fibers forward out of the fiber supply. On the right, I am loosening the fibers from side to side.

Cashmere/Merino

Isn’t it dreamy? I used this blend for the Chinese Tiles Scarf from Spin Off Summer 2016 and wanted to make another. This combed top is a blend of two fibers with different staple lengths. Predrafting changes the density of the fiber and gives the shorter cashmere an opportunity to separate from the longer Merino fibers. This leads to a more textured yarn. If I open the fibers laterally (side to side) very gently and then give the fibers a gentle, non-drafting tug on the end, it will restore the loft that dyeing and compaction pressed out.

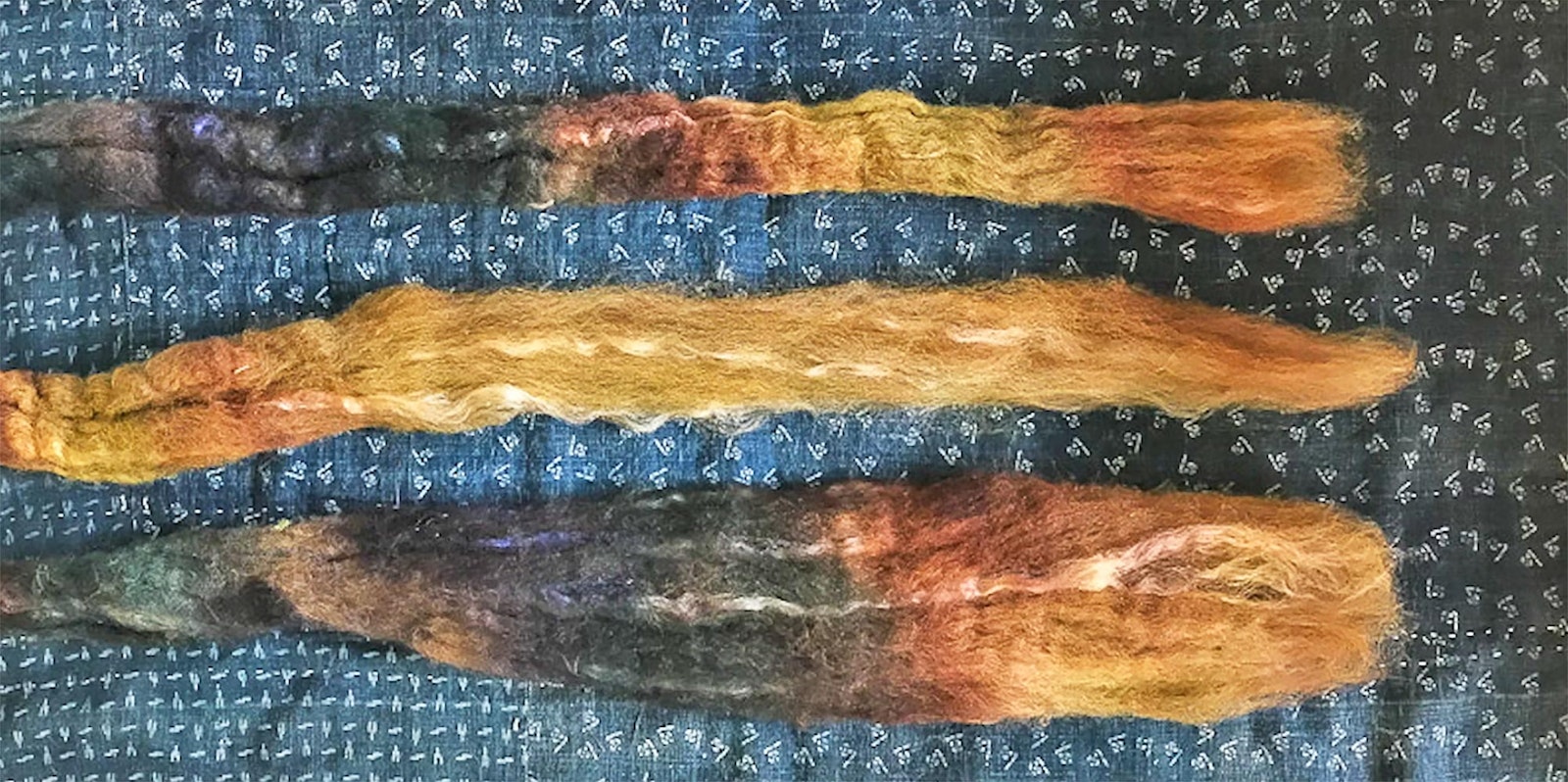

See the staple length difference between combed Merino and cashmere. Loosening the fibers can keep them blended and organized while improving drafting during spinning.

See the staple length difference between combed Merino and cashmere. Loosening the fibers can keep them blended and organized while improving drafting during spinning.

Cotton Silver

I spin mostly natural-colored cotton on my charkha and wanted to give handpainted cotton a try. Cotton generally compacts very easily, and this gem was squashed in the bottom of my spinning basket. The light compaction combined with a nice, long staple length meant that I had to draft with more tension than usual, which didn’t work well for my lightweight book charkha. I wanted to loosen the fibers but not lose the dyed effect. Cotton fibers are relatively short, so my small sample of pre-drafted sliver had intermittent thicker and thinner spots, causing my yarn to do likewise. Loosening the spinning fibers laterally improved drafting while keeping the fibers close enough together for fine, smooth spinning.

Even a long-staple cotton is relatively short compared to most spinning fibers. Loosened laterally, this sliver spins easily. Handspun cotton cloth, here I come!

Even a long-staple cotton is relatively short compared to most spinning fibers. Loosened laterally, this sliver spins easily. Handspun cotton cloth, here I come!

Kate Larson, editor of Spin Off, teaches handspinning around the country and spends as many hours as life allows in the barn with her beloved flock of Border Leicesters.

Originally published October 17, 2017; updated September 16, 2024.