“You cannot treadle your way out of trouble.”

—Alden Amos

The Alden Amos Big Book of Handspinning (Interweave, 2001)

When things go right in spinning, life is beautiful and effortless. When things go wrong, we mutter nasty things to our fiber and wheels. Instead of getting angry, stop, take a deep breath, and relax. Take a short break to get perspective. What is really going on? Below is a checklist of problems and some possible solutions. Sometimes it is the wheel, sometimes it is the fiber, and sometimes it is the spinner that is the source of the problem. Remember, we have all had these problems whether we’ve spun for forty years or four days. All solutions are simple if you know the troubleshooting possibilities.

Wheel Goes Backward

• When spinning to the right (Z), start the wheel with the footman in the one o’clock position and then make the first treadle strong to get momentum.

• Slightly decrease the tension on the drive band or brake band.

Wheel is Hard to Treadle

• Make sure your wheel is clean and oiled.

• Slightly decrease the tension on the drive band or brake band.

• Check the maidens and make sure they are parallel (if one is awry, it is like having another brake).

Yarn Won’t Wind onto the Bobbin

• Remember to feed yarn to the wheel. Relax your grip so the yarn can wind onto the bobbin.

• Check the hooks or guides on the flyer for yarn that is snagged or looped around a hook.

• If the yarn becomes too twisted, it won’t wind on. You will need to unwind some of the kinks before starting again. Stop treadling and draft out more fibers to give the twist somewhere to go.

• Slightly increase the tension on the drive band or brake band.

• Make sure the brake and tension bands are in the right places. On a double-drive wheel, one loop of the drive band needs to be on the flyer and one loop on the bobbin.

• On a double-drive wheel, the flyer whorl should have a larger diameter than the bobbin whorl so the yarn can wind on.

• Check the leader. To prevent slippage, tie it tightly to the bobbin shaft.

• Does the flyer rotate freely around the flyer shaft? If it doesn’t, wipe down the shaft with a cotton swab or rag. If the bobbin is still tight, wrap a little sandpaper around a dowel and use it to clean out the bobbin shaft, or better yet, contact the wheel manufacturer for advice.

• Check to see if the bobbin ends are loose or missing. Replace or reglue them.

• See if any yarn has wrapped around the base of the flyer shaft. Rewind the yarn back onto the bobbin if it isn’t greasy. Note that petroleum-based oils on the flyer shaft may not wash out of the yarn.

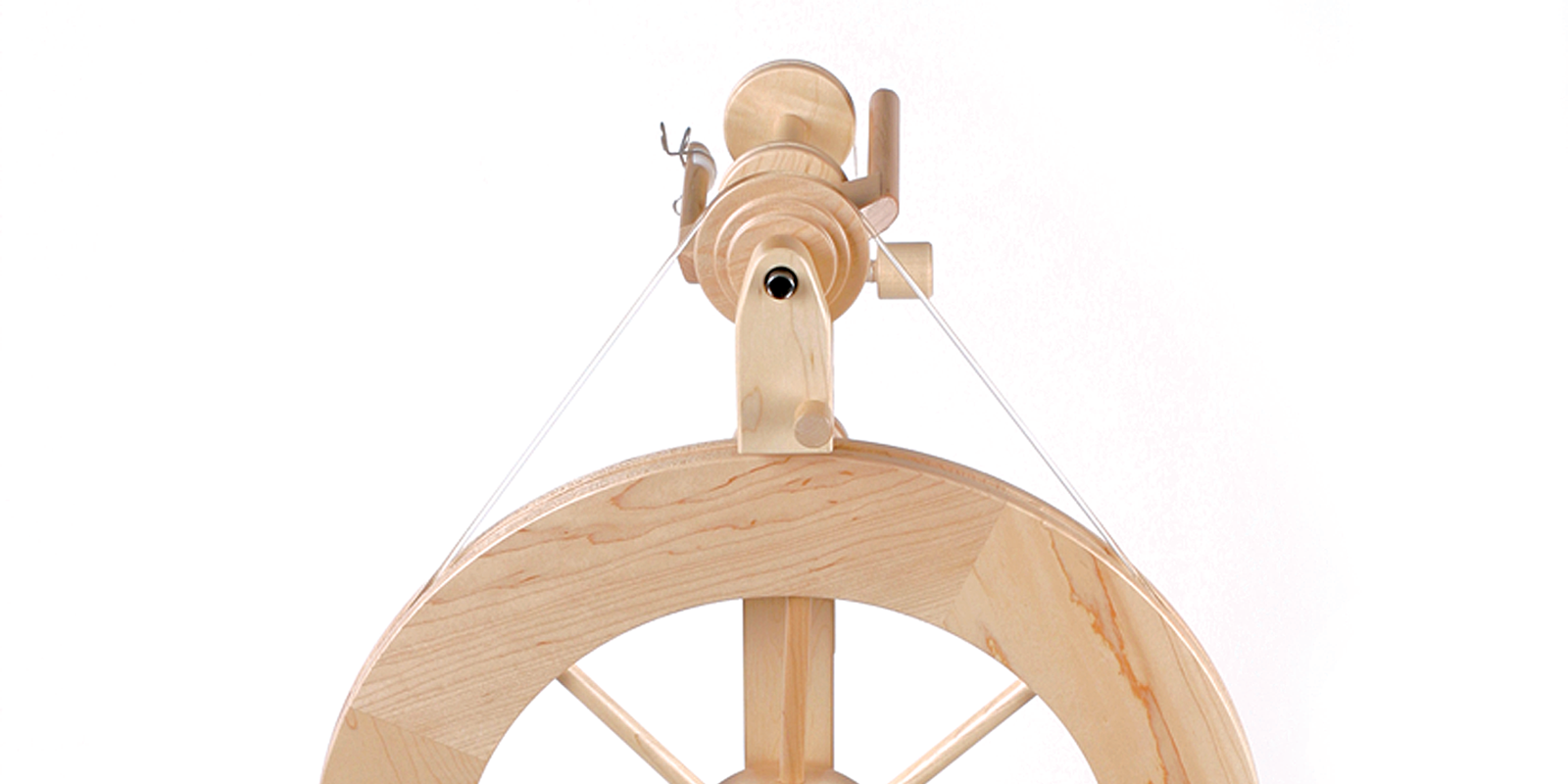

Traditional or Saxony wheel

Traditional or Saxony wheel

Yarn is Getting Too Much Twist and May Break

• Remember to feed the yarn to the wheel.

• Slightly increase the tension on the drive band or brake band to increase take-up.

• If your wheel has several whorls, change to a larger one to get fewer twists per treadle.

• Make sure your drive band has not slipped to a smaller whorl.

• Try drafting a little faster and treadling slower.

Flyer Won’t Turn When the Wheel is Treadled

• Slightly increase the tension on the drive band.

• On wheels with self-adjusting drive bands and no way to increase tension, your band may be stretched out. You may have to buy a new drive band.

Yarn Doesn’t Have Enough Twist and Drifts Apart

• Slightly decrease the tension on the drive band or brake band so the yarn will twist more.

• Go to a smaller diameter whorl to get more twists per treadle.

• Draft more slowly to allow more twist to enter the yarn.

• Treadle faster.

Parts of a wheel configured for double-drive

Parts of a wheel configured for double-drive

Yarn is Pulled Out of Your Hands and onto the Wheel

• Slightly decrease the tension on the brake band or drive band.

• If using a WooLee Winder, it may be time to clean it.

Join Doesn’t Hold

• Join fuzzy to fuzzy—untwist the fiber about 1 inch on each end. Overlap these and carefully draft them together. Treadle a little extra to hold the join together. Untwist the yarn end about 1 inch. Predraft the other end. As you treadle, catch fibers in the twist until you have passed the twist. Treadle a little extra to hold the join together.

• When all else fails, tie a knot. You can fix it later.

Looking to learn more about spinning wheels? This and other articles can be found in the Fall 2011 and Fall 2022 issues of Spin Off.

Also, remember that if you are an active subscriber to Spin Off magazine, you have unlimited access to previous issues, including Fall 2011 and Fall 2022. See our help center for the step-by-step process on how to access them.

Resources

Amos, Alden. The Alden Amos Big Book of Handweaving. Loveland, Colorado: Interweave, 2001.

Casey, Maggie. Start Spinning. Loveland, Colorado: Interweave, 2008.

Denise Jackson of central Montana is a fourth-generation spinner and weaver. She would like to extend her thanks to Lisa Wilson of Fiber Frontier.

Originally published June 26, 2020; updated December 2, 2022.