I have been asked what to do when a top-whorl spindle wobbles during spinning, so here’s a diagnostic checklist for you top-whorl spindlers:

- Check operator technique. Make sure your spindle is vertical when you finger flick it, so you’re sure it isn’t you causing the wobble.

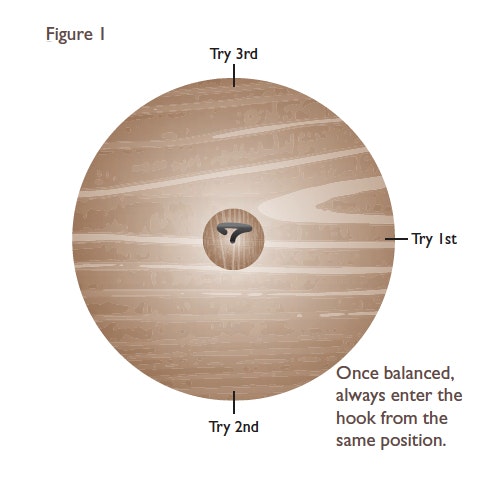

- See if putting the yarn through the hook from a different position (fig. 1) stops the wobble or makes it worse.

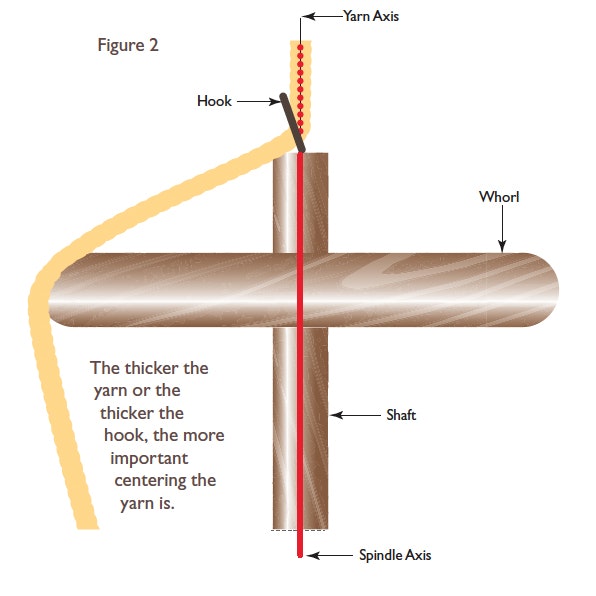

- Look at the hook. Does it need to be tweaked to one side, forward, or backward? If it needs to be tweaked, first check what kind of hook you have. Not all hooks can be adjusted, and a cast hook will break. If your hook can be adjusted, reinforce the shaft by holding it tightly where the hook enters the shaft, then gently, and with small movements, tweak the hook until it centers the yarn being spun (fig. 2). Spin to check the new placement. Repeat the sequence, tweaking and test spinning as needed, but be very careful: too much tweaking will cause metal fatigue and break even a flexible hook.

If your hook can’t be adjusted, you may need to contact the spindle maker. Good spindle makers are proud of their work and want you to enjoy your spindles, so they are a good resource for solutions. And one last word of advice: never leave your spindle on the floor or around puppies (I speak from experience). But if disaster strikes, contact the spindle maker for repairs so you can once again enjoy using your beautiful tool.

Jeannine Glaves of Tulsa, Oklahoma, loves spindles! She lost count many spindles ago but is always on the lookout for beautiful or unusual additions to her collection. She believes anything worth doing is worth overdoing and is anticipating a new addition to the collection any day now.

This article was published in the Fall 2013 issue of Spin Off.